Infrared assisted Refractance Window Drying (InfraRWD)

Infrared assisted refractance window drying (InfraRWD) utilizes both radiation and conduction as a heat transfer mechanism to dry your product.

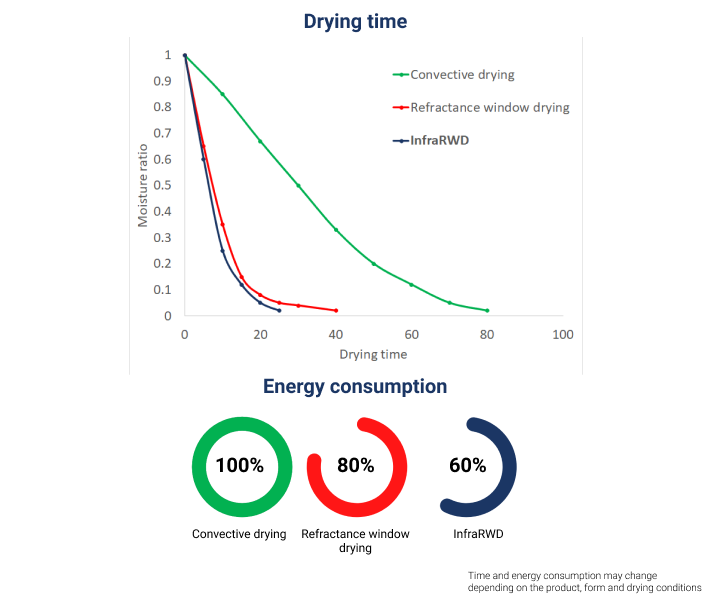

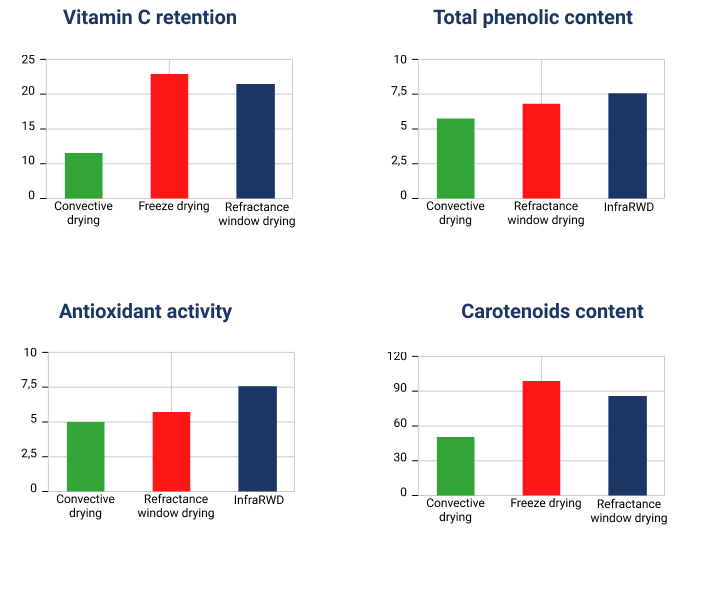

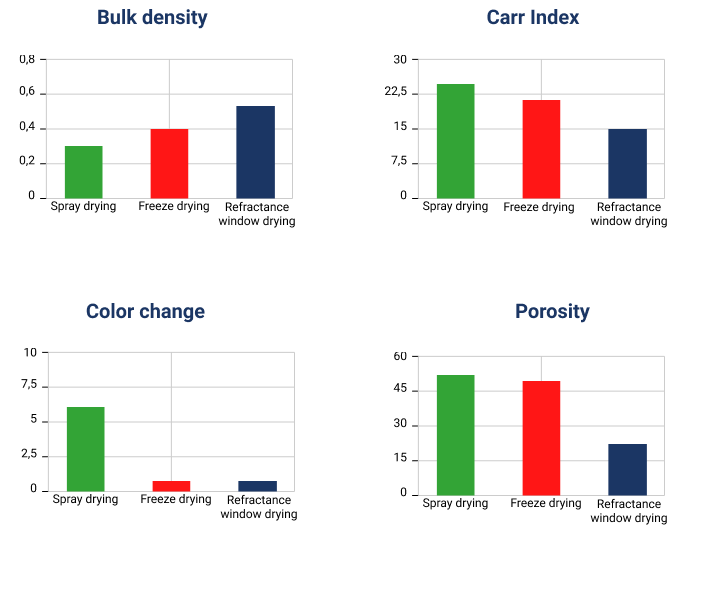

Its unique properties achieve much shorter drying times and higher quality compared to other drying systems.

Main advantages

InfraRWD have many advantages over other drying techniques including freeze drying, spray drying and drum drying.

Steps of InfraRWD

InfraRWD is continuous drying system that achieves drying in three main steps

-

1

Material application

Refractance window drying works based on the refractive principle of infrared radiation from hot water to dried material. In this technology fluid or semi-fluid wet material spreads on an infrared transparent plastic sheet as a thin layer. The plastic sheet moves over the hot water and thermal energy is carried out to the dried material by combined conduction and infrared radiation. Infrared lamps over the dried material ensure double sided heat transfer.

-

2

Drying

The moisture of material contacts with the plastic sheet over the hot water provides allowing the transfer of infrared heat energy through the sheet to the material to be dehydrated. That's why there is a window expression in the method name. This process is self-governing; because decreasing moisture content causes gradual closing of the infrared window.

-

3

Final product

Scientific studies showed that radiation mechanism only provides 5% of contribution. Despite this low contribution, the refractance window drying process results in higher drying rate, more retention of nutrients and low aroma and flavour loss in different products compared to other drying systems

Applications

InfraRWD can be used in drying of a wide range of products from foods to chemicals.

Fruits and vegetables

InfraRWD provides high quality not only in chemical composition but also physical properties.

Dairy and proteins

InfraRWD offers high quality in dairy powders and plant based proteins in terms of physical and chemical properties.

Algae

Gentle conditions during InfraRWD cause minimum change in heat sensitive constituents of algae.

Pharmaceuticals

InfraRWD not only offers maximum retention of active components but also allows high yield and long shelf life