What is microencapsulation?

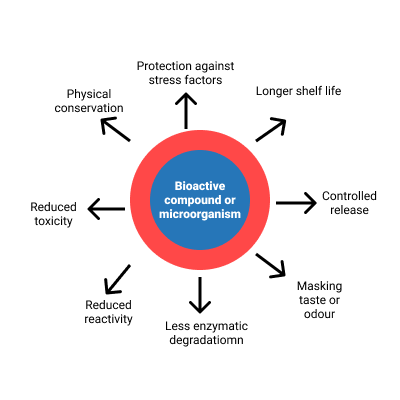

Microencapsulation is basically defined as the coating or entrapment of solid, liquid or gas material within another material. By encapsulation superior properties can given to the bioactive material.

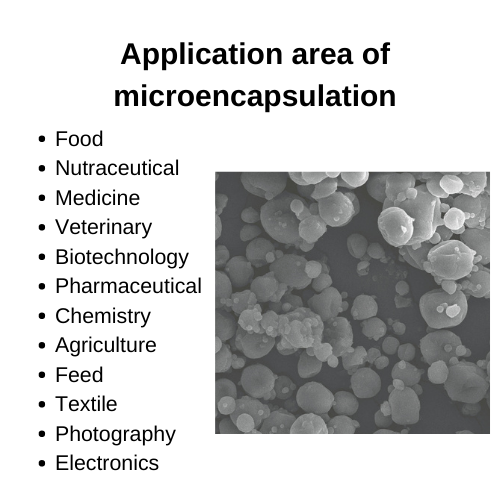

These effects can be listed as;

- Active material can be control released as in shorten ripening time of cheese production

- Oxidative reactions can be prevented by this way omega-3 or essential fatty acids protected from oxidation

- Masking of flavours, colours and odour substances as in ferric ions

- Protection of active material during gastric passage as in probiotic microorganisms

Common techniques in microencapsulation

Nowadays, these valuable benefical effects of encapsulation makes it unreplaceable food processing methods. There has been several encapsulation techniques. As a common aspect, a dried powder form is obtained after encapsulation.

Spray drying is mostly used encapsulation technique in food processing. In spray drying, a liquid or slurry mixture of active and wall material is atomized into a hot gas stream. By this way, powder form of liquid material can be obtained. In the food sector, this is the favored method for drying emulsions such flavor oil emulsions, probiotics, vitamins, minerals, etc.

However, microencapsulation is carried at high temperatures in spray drying that cause irreversible changes in the bioactive food compounds. Additionally, high drying temperatures can be resulted the deteriorate effect on flavor and aroma of final product by increasing non enzymatical browning reactions. On the other hand, for effective atomization in spray drying, the viscosity of liquid should be as low as for pumping. To this purpose, the dry matter of liquid or slurry is generally adjusted to 20-30 g/100g. This situation limits the capacity of microencapsulation.

Microencapsulation by refractance window drying

For these reasons, the food industry seeks for new microencapsulation methods that enabling microencapsulation at lower temperatures. Refrectance window drying is one of the most promising encapsulating methods. It allows to production of microcapsules at lower drying temperatures for minutes.

In a recent study, probiotic lactic acid bacteria encapsulated by refractance window drying. High viability rates (9 log cfu/g) in the microcapsules could be obtained at low drying temperatures. By this study, it is revealed that refractance window drying may be used in the microencapsulation of probiotic microorganisms (Aragon-Josas et al., 2019).

In another study, a symbiotic microcapsule was produced by refractance window drying. The results show that refractance window drying ensured similar moisture content and water activity in microcapsules. Low moisture and water activity content is the main factor effects the stability of microcapsules. Physical properties of microcapsules such as bulk density Hausner ratio, Carr’s index and flowability are also important parameters for microcapsule technology.

In the same study, better physical features were obtained in refractance window dried microcapsules when compared with freeze drying. Additionally, by refractance window drying more lightness color values could be ensured in microcapsules. These result also revealed that non-enzymatic browning reaction does not occur at low drying temperatures at refractance window drying process.

Moreover, refractance window drying ensured more stability to microcapsules in gastric transit higher than frezze drying. (Yoha et al., 2019). As another advantage of refreactance window drying, the powder yield is nearly 100%. However, the product yield decrease in spray drying because of high drying temperatures and lesser liquid viscosity.

Need mor information about our technology, you can read Refractance Window Drying Technology post.

Interested in our dryers, get more information on our services page.

References

Aragón-Rojas, S., Quintanilla-Carvajal, M.X., Hernández-Sánchez, H., Hernández-Álvarez, A.J., Moreno, F.L. Encapsulation of Lactobacillus fermentum K73 by Refractance Window drying. Scientific Reports, 9:5625.

K. S. Yoha, J. A. Moses & C. Anandharamakrishnan (2019): Conductive hydro drying through refractance window drying – An alternative technique for drying of Lactobacillus plantarum (NCIM 2083), Drying Technology, DOI: 10.1080/07373937.2019.1624972