Refractance Window Drying is an effective and developing drying technology used for drying liquid, semi-liquid and slices forms of fresh whole food. Recently, Refractance Window Drying technique is seen as an advanced method in terms of drying parameters and product properties compared to the negative aspects of existing drying techniques. Refractance Window Drying technology has advantages on many parameters such as scalability, energy efficiency, cost and end-product quality.

Drying technologies are classified as first, second, third or fourth generation. First-generation dryers are specified as cabinet and bed type dryers such as kiln, tray, truck tray, rotary flow conveyor and tunnel using hot air as the medium of heat transfer. Spray and tumble dryers belong to the second generation, while freeze dehydration and osmotic dehydration belong to the third generation drying technologies. Microwave drying, infrared drying, heat pump drying, fluidized bed drying, radio frequency drying and Refractance Window Drying are found in the fourth generation.

Mechanism of Refractance Window Drying Technology

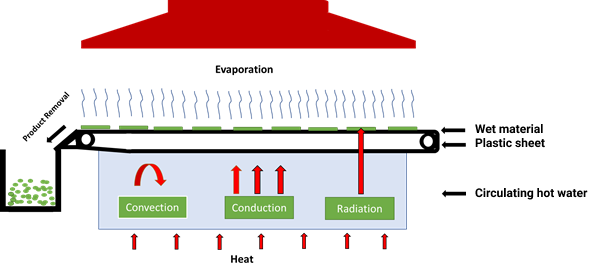

Three different heat transfers occur in the Refractance Window Drying system during drying as conduction, convection and radiation. In general, conduction heat transfer is dominant in the system ,but each form of heat transfer occurs in different parts of the drying system. Conduction, convection and radiation occur at the hot water-flim interface; conduction and radiation throughout the film; convection at the air-flim interface.

In the Refractance Window Drying system, the high-moisture product is placed on a thin plastic film and the material is dried by heating the film layer from below with hot water circulation. The thin plastic film layer creates a ‘window’ in the system in which allow heat and mass transfer from hot water to moist material. This ‘window’ allows the infrared energy to pass from the high-moisture product placed on the plastic film.

As the moisture decreases in the product, the window gradually closes and the transmission of thermal radiation decreases. The material is prevented from reaching the water bath (95-97° C) temperatures with the close of the window. RWD system uses circulating water molecules at 95-97°C and at atmospheric pressure to provide heat transfer to the product, and the product temperatures generally remain below 70°C.

During the drying process, the thermal energy transmitted at the film layer-product interface is absorbed by the high-moisture product and the product starts to dry. With drying, moisture evaporates from the product. Rapid evaporation of water is provided to eliminate the effects of intense water evaporation and air gap in the product.

At the end of the drying process, the material is passed over the belt cooled with cold water from below, and separated from the belt by the scraper device. The cooling part is to reduce the product’s temperature below the glass transition temperature and to prevent product stickiness.

Parameters of Refractance Window Drying Technology

The RWD technique is affected by various process parameters, including water bath temperature, mylar film thickness, loading rate, sample thickness, relative humidity, and air velocity. Among these, film thickness, air velocity, and temperature are easily controllable primary parameters, while loading rate and sample thickness are secondary parameters.

The plastic film commonly used in RWD technology is Mylar. Mylar is a polyethylene terephthalate (PET). The amount of energy conducted and radiated from the Mylar layer change according to the temperature of the heating source, the thickness of the flim, the thickness of the product and the humidity of the product.

Mylar film thickness is an important parameter, and the film mechanical strength decreases with increasing film thickness. Also, the thicker film results in relatively lower conductive heat transfer, which requires a longer drying time. Therefore, the unit price of thinner films is higher than that of thicker films. In other words, the use of thinner film increases the operating cost. Considering each parameter, the optimum thickness is specified as 0.25 mm.

Mylar is the ideal flim layer in RDW technology with a thermal conductivity of 0.24 W/mK, a density of 1.39 g/cm3 and a specific heat of 0.28 Cal/g/°C under ambient conditions. The Mylar layer provides higher radiation heat conduction at higher heating temperature and thinner film layer thickness. RWD technology provides rapid transmission of heat through conduction, convection and radiation and so ensures a shorter drying time and higher product quality.

The shorter the exposure time to heat, the lesser changes occur in the color, flavor, aroma and nutritional value of the product. In addition, better retention of bioactive compounds such as vitamins, minerals and phenolic compounds in the product and better inhibition of microbial growth during the drying process are provided with RWD technology.

In addition, RWD technology is of some important properties such as better retention of bioactive compounds such as vitamins, minerals and phenolic compounds in the product and better inhibition of microbial growth during the drying process.

Refractance Window Drying is an ideal drying technique that can be used to obtain heat sensitive purees, fruit slices, fruit and vegetable powders, meat and dairy powders, plant extracts and human nutritional supplements and food additives. Also, RWD technology can be found a use possibility in the algae containing high carotenoids, pharmaceutical, nutraceutical, cosmetic and pigment processing industries thanks to the many advantages.

Drying of the product takes a few hours with hot air tray or tunnel dryers and 12-72 hours with freeze dryers, while this time is shorter (2-6 min) in the RWD system. In RWD technology, a high energy saving is achieved by using less energy. The system shows high drying efficiency and effectiveness with less energy. The recyclability and usability of hot water used for heating improve the thermal efficiency of the system. The thermal efficiency of RWD systems is generally in the range of 52-77%. Other hot air dryers provide only 50% efficiency when compared to RWD systems.

The capacities of RWD systems are comparable scale with spray dryers and drum dryers. In terms of installation economy, it is simple and relatively inexpensive compared to freeze drying, which often requires large installations. RWD technology has a very high cost advantage and can dry a similar amount of freeze-dried product at one-third the cost of a freeze dryer. The energy costs of the Refractance Window Drying Technology are less than half that of freeze dryers.

More than 85% of industrial dryers perform the heat transfer as convection in hot air or combustion gases medium, resulting in higher drying times resulting in poor quality products. RWD systems are a drying technique designed to eliminate the existing disadvantages (installation cost, drying cost, drying time, component protection, etc.) in drying systems.

Advantages of Refractance Window Drying Technology

- Low drying temperature

- Short drying time

- High energy efficiency

- Retention of bioactive components

- Retains complex, subtle flavors and aromas as well as colors and nutrients

- No need for chemical additives

- Obtaining higher quality products

- Possibility of drying high sugar products

- Since the product does not come into contact with the heat transfer medium, cross contamination does not occur.

- Low cost of equipment

- Low drying cost

Applications of Refractance Window Drying Technology

- Fruits and Vegetables – purees, juices, pulps, slices

- Meat, Fish, and Poultry – purees

- Dairy and Egg products, including dairy cultures

- Cereals, Grains, and Starches

- Flavors and Colors

- Beverages – concentrates and mixes

- Nutraceuticals

- Pharmaceuticals

- Fine Chemicals

Fruit and vegetables have high nutritional value such as vitamins, minerals, carotenoids, phenolic compounds, flavonoid compounds, non-flavonoid compounds, etc. These components affect importantly from high temperatures. In spray drying, tunnel drying, drum drying, etc. techniques apply high temperatures at different times (min and hour).

So, the Refractance Window Drying Technology has an important advantage in terms of dried products exposed to low temperatures. The nutritional quality of the product is protected in quite a high proportion with the RWD technique. Moreover, the powder properties of dried products are comparable level with freeze dried products. However, a large-scale freeze drying system has a very high installation cost. For this reason, RWD is an ideal drying system that product can be obtained with low temperature, low drying time and low installation cost.

Considering the studies in the literature and industry, drying of products such as tomato powder, mango slices, asparagus leaves, carrot puree, chickpea protein isolates, asparagus puree, strawberry puree, yoghurt, etc. was carried out with the Refractance Window Drying Technology.

To discover more about our InfraRWD dryers you can visit technology page and contact us about our wide range of services.

InfraRWD is produced by NFDS Arge.